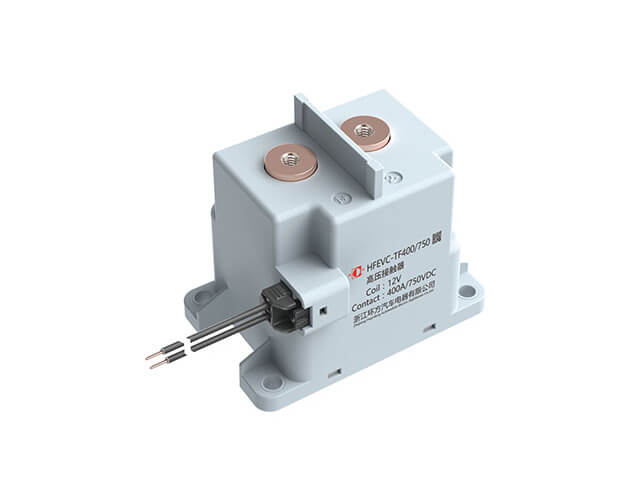

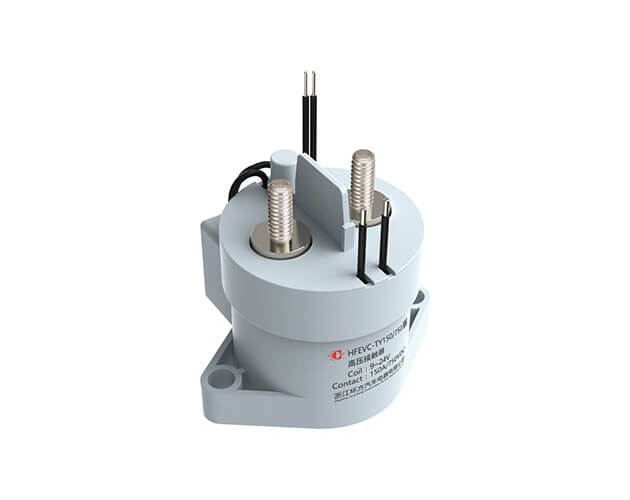

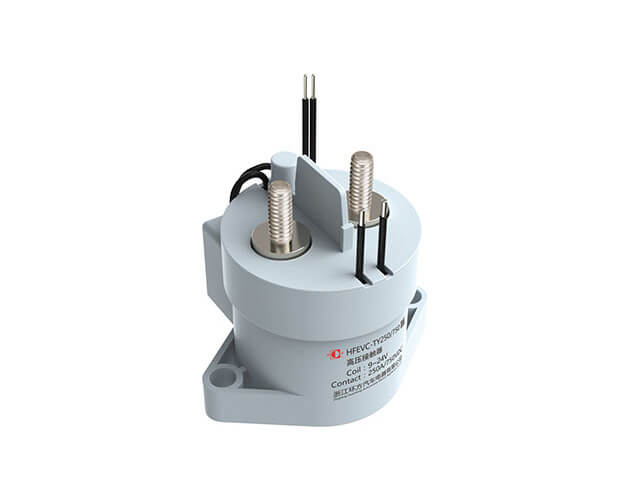

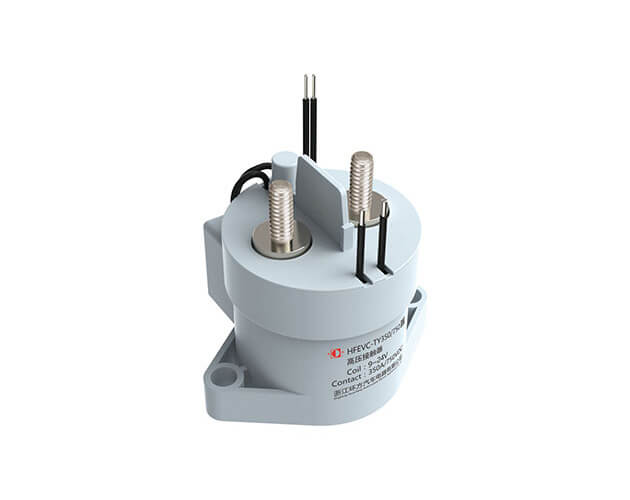

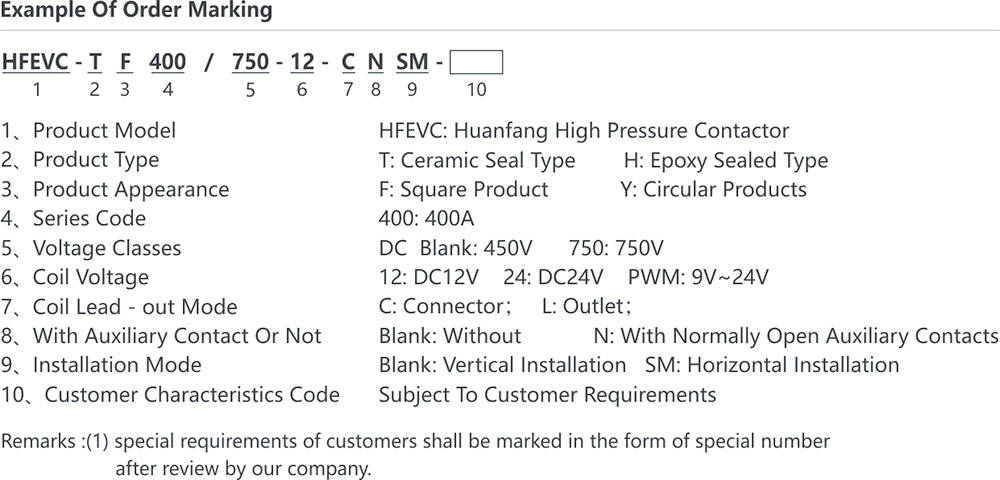

HFEVC-TF400

Product Features

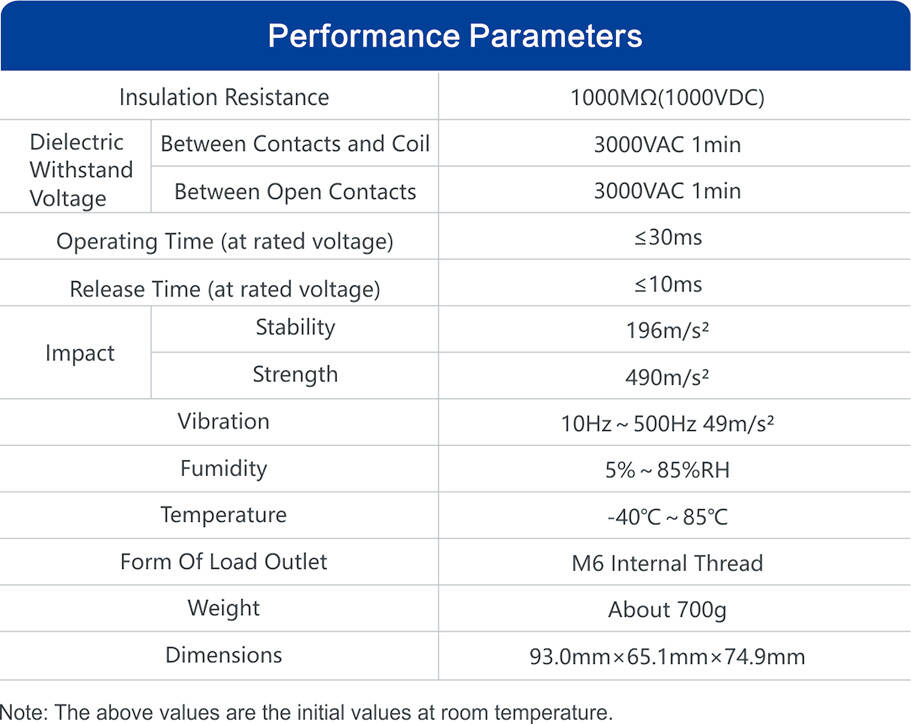

- Ceramic vacuum brazing seal is adopted to ensure no arc leakage, and the contact point can meet the protection grade of IP6K9K.

- The mixed gas mainly filled with hydrogen can quickly cool the arc and prevent the contact from oxidation and burning.

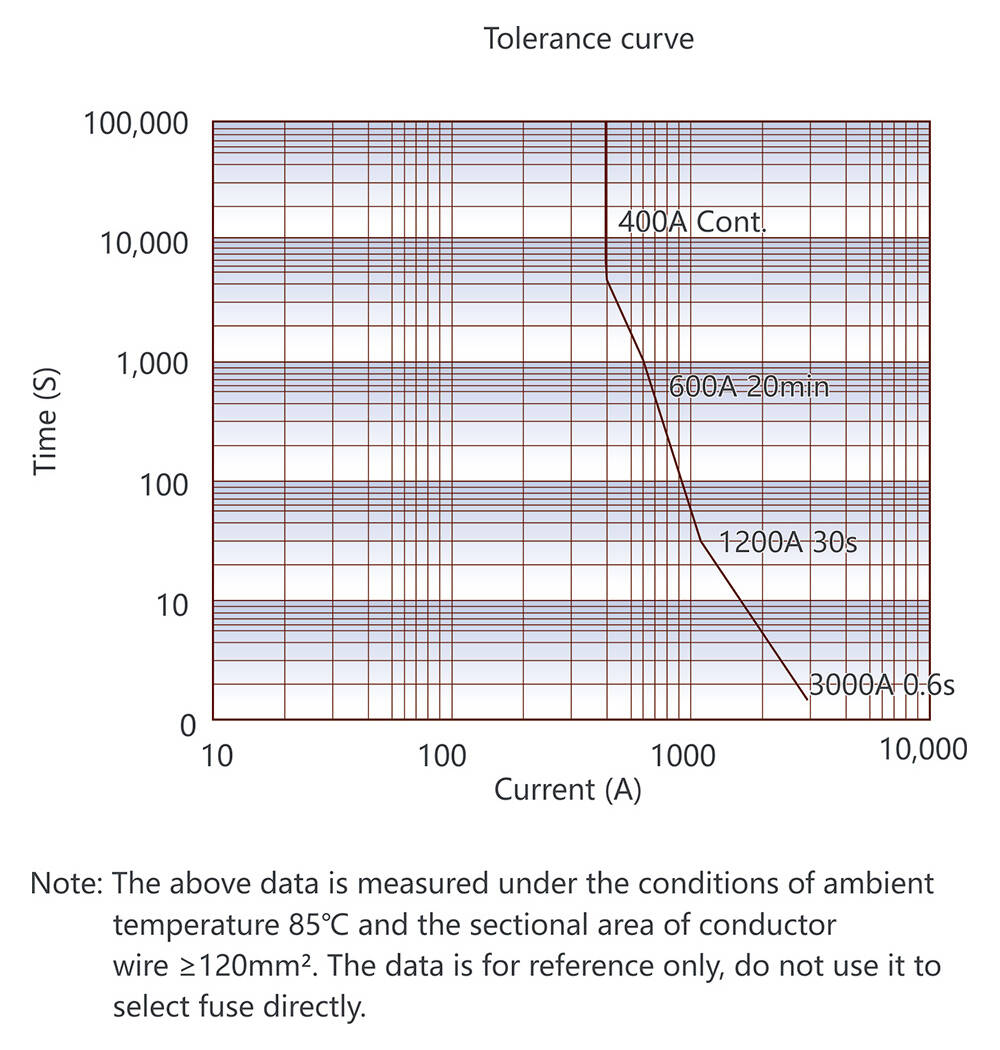

- 400A 85°C long time current carrying capacity.

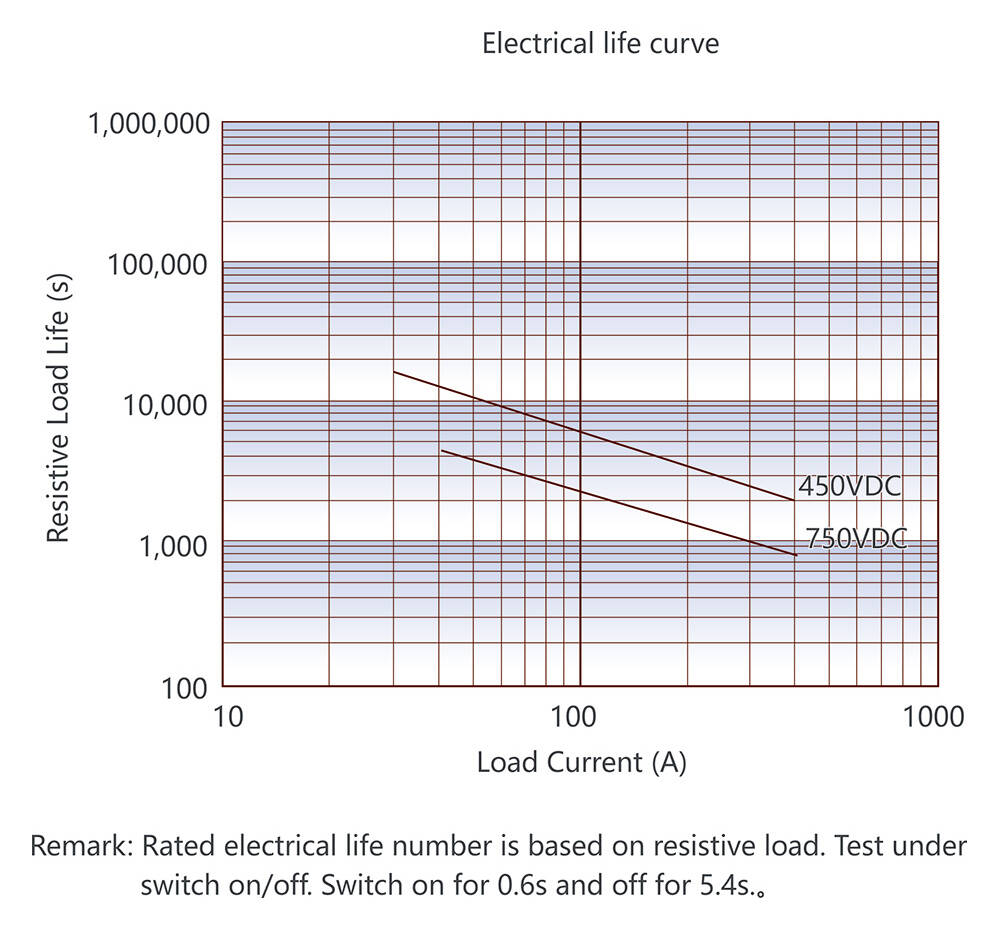

- The rated voltage of cut-off load is 12-750VDC.

- The insulation resistance reaches 1000m Ω (1000VDC) and meets the requirements of IEC 60664-1.

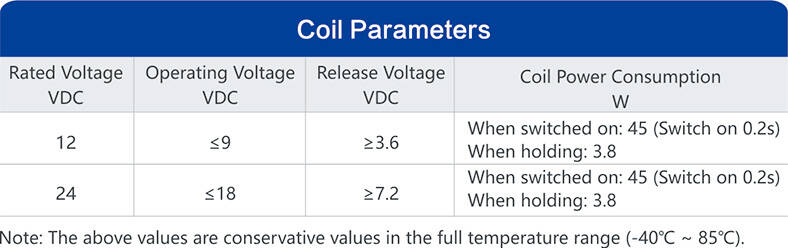

- Energy saving type: control by Double coil PCB board ,when at low power consumption, product can keep in incentive condition.

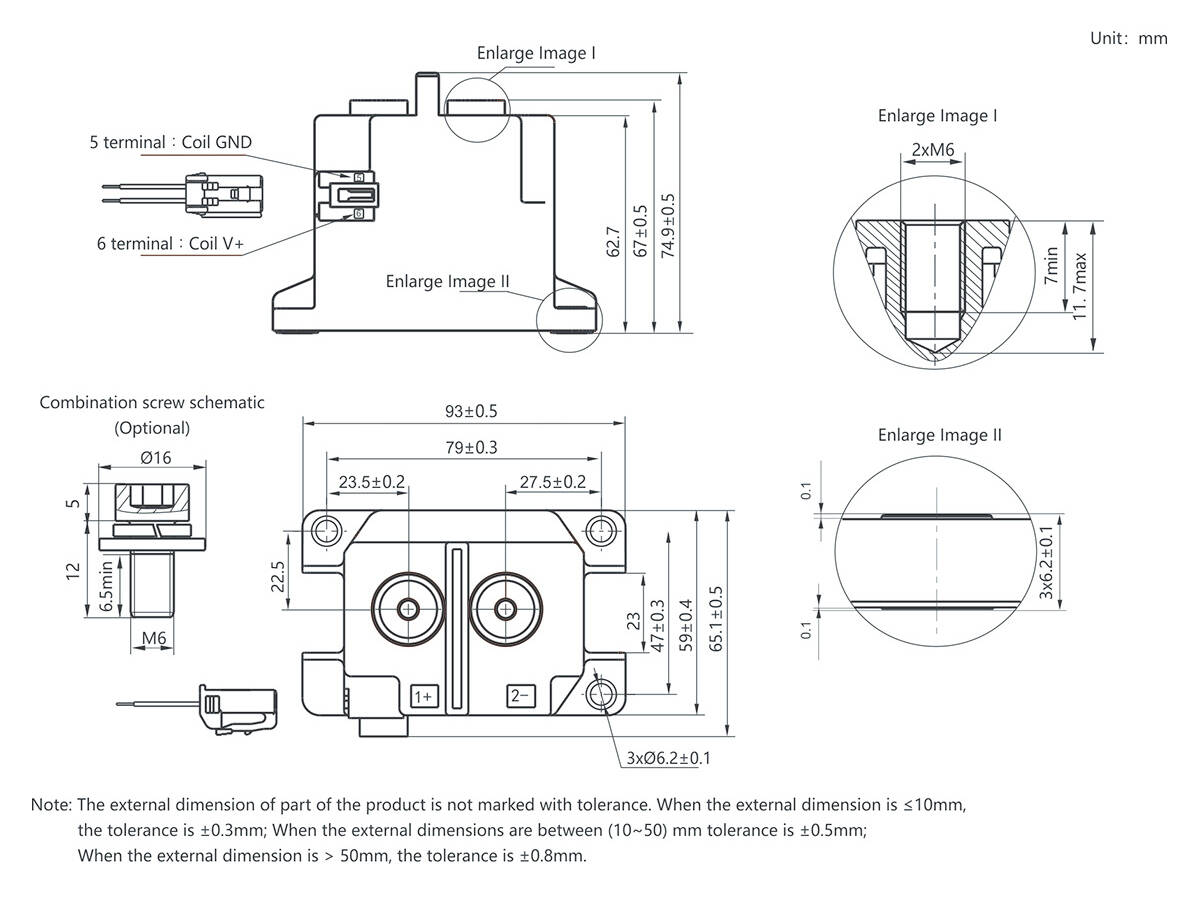

Outline drawing, mounting hole size:

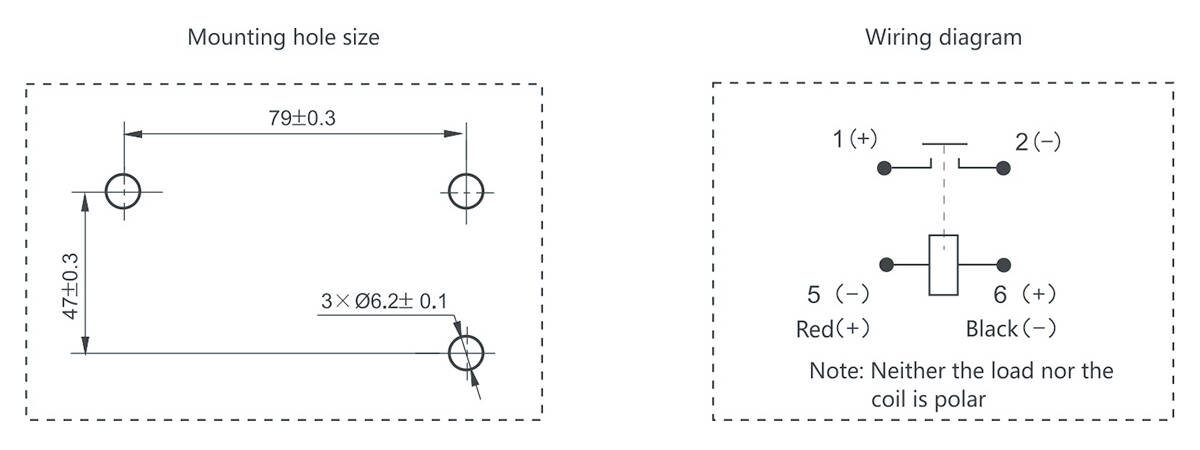

Mounting hole size/Wiring diagram:

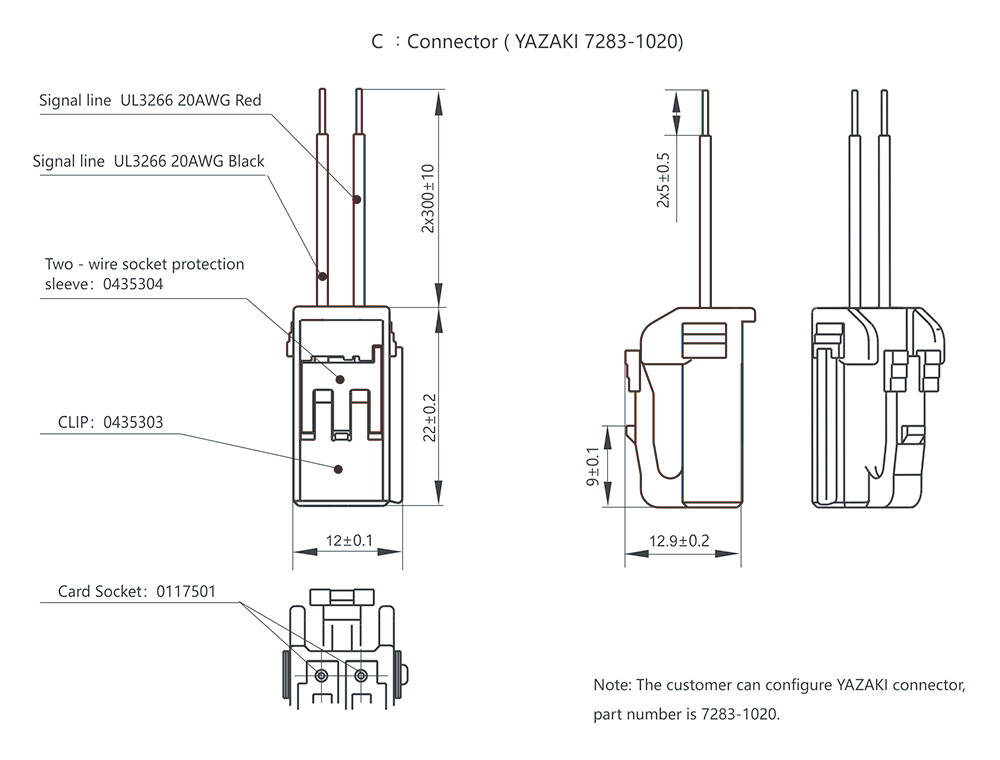

Coil take-up form:

Precautions For Use

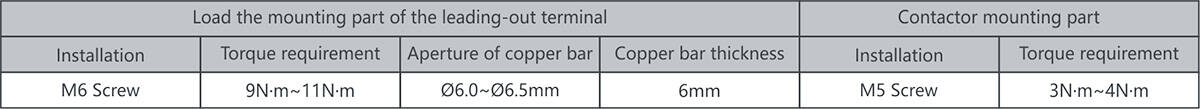

1. To prevent looseness, use a gasket when installing the contactor. Please use M5 screw at contactor installation. Screw locking torque should be controlled within 3N·m~4N·m; The screw locking torque at the installation of the leading end should be controlled at 9N·m~11N·m. In case of exceeding the range, it may cause damage.

2. Avoid sticking grease and other foreign bodies on the leading-out piece, and use the connection wire of 120mm² or above, otherwise abnormal heating may be caused at the leading-out end.

3. The product is built with an energy-saving board. The coil will switch after 0.2s is driven, but the repeated on/off operation < 0.2s will cause contactor failure.

4. The product with built-in circuit board cannot be driven by slow rising voltage. Please drive the coil by fast rising edge (step power supply mode), otherwise it won’t move!

5. It is recommended that the thickness of copper strip be 3mm, otherwise it will cause the problem of thread sliding teeth or loose installation.

Statement

1. The document is for customer reference only. Huanfang has made every effort to ensure the accuracy of the information in this document. However, mistakes are inevitable, and the products, specifications and parameters may be changed due to product improvement. For the specific parameters and performance of each product, please refer to the specifications and samples provided by Huanfang without further notice.

2. As for the application field, it is impossible for Huanfang to evaluate all performance parameters of contactor in each specific application field. Therefore, customers should select the products matching with the contactor according to the specific service conditions. If the requirements are not specified clearly, please contact Huanfang for more technical support. Huanfang clearly states that the information in this document is only for selection reference, and the responsibility of product selection is only the responsibility of the customer.